|

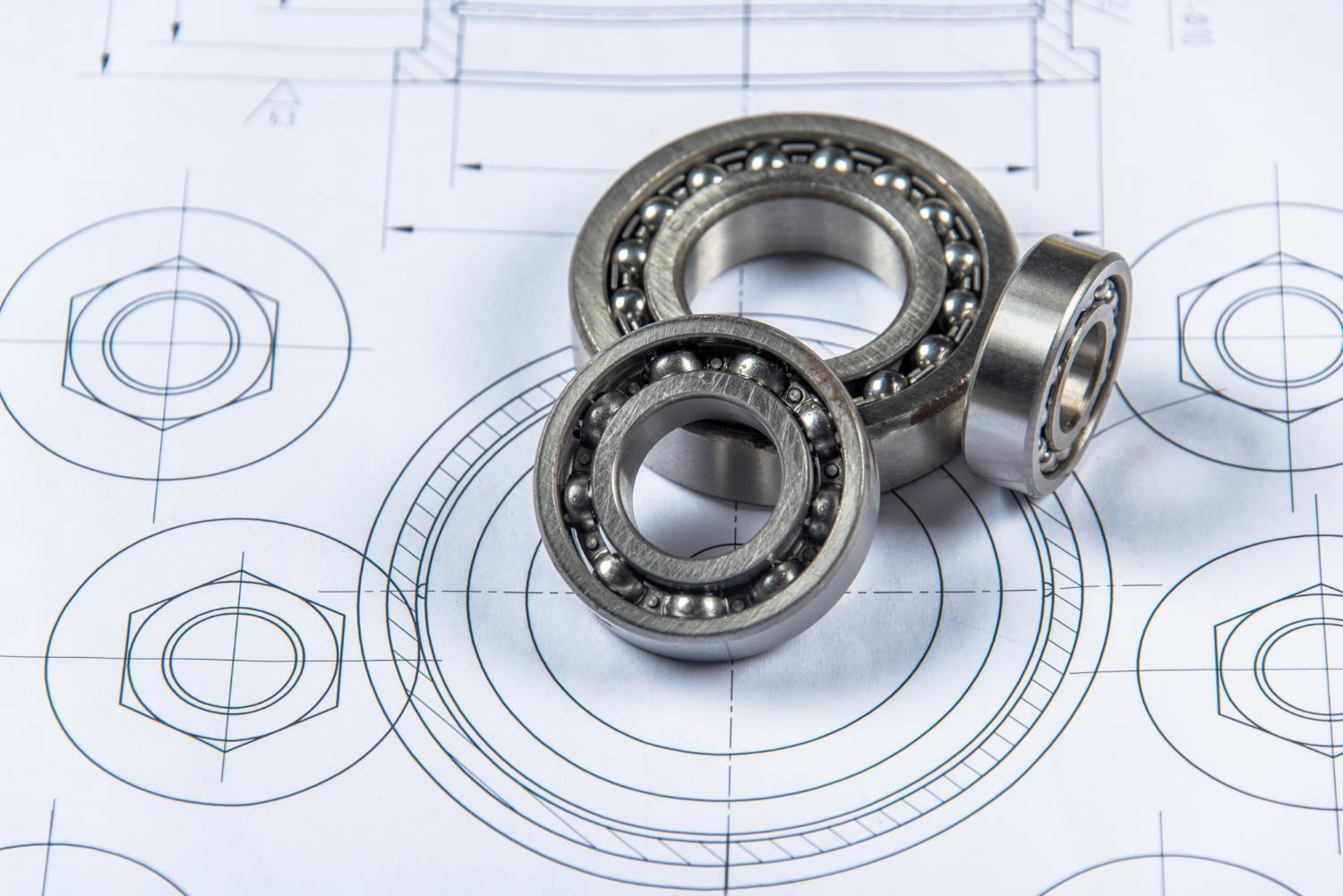

Selecting the proper material for ball bearings is essential, as it depends on operational conditions and specific application requirements. Among the most common options, steel, ceramic, and hybrid bearings stand out—each offering unique advantages tailored to different industries. Steel bearings are known for their durability and ability to handle heavy loads. Ceramic bearings provide lightweight construction and corrosion resistance, making them ideal for high-speed, low-friction applications. Hybrid bearings combine the strengths of both materials, balancing performance, durability, and cost. By carefully evaluating the properties of each material, it is possible to select the ideal bearing to optimize performance, extend service life, and ensure reliability in industrial processes. Selecting the proper material for ball bearings is essential, as it depends on operational conditions and specific application requirements. Among the most common options, steel, ceramic, and hybrid bearings stand out—each offering unique advantages tailored to different industries. Steel bearings are known for their durability and ability to handle heavy loads. Ceramic bearings provide lightweight construction and corrosion resistance, making them ideal for high-speed, low-friction applications. Hybrid bearings combine the strengths of both materials, balancing performance, durability, and cost. By carefully evaluating the properties of each material, it is possible to select the ideal bearing to optimize performance, extend service life, and ensure reliability in industrial processes. Steel BearingsSteel is the most widely used bearing material thanks to its high durability and wear resistance. It is a preferred choice in industrial and automotive sectors where components must withstand heavy loads and perform reliably in demanding environments. Applications

Disadvantages Ceramic BearingsCeramic bearings are valued for their exceptional corrosion resistance, enabling them to operate in extreme conditions where traditional lubrication may not be viable. They are particularly advantageous in high-temperature environments and in industries exposed to chemicals. Another key advantage is their lighter weight compared to steel, which contributes to higher efficiency, lower friction, and reduced energy consumption—critical factors in sectors like aerospace and motorsports. Limitations In summary, ceramic bearings are ideal for applications prioritizing speed, efficiency, and resistance to corrosion, even if the initial investment is higher. Hybrid BearingsHybrid bearings combine steel rings with ceramic rolling elements, creating a solution that leverages the strengths of both materials. This design provides structural robustness from steel and lightweight, corrosion-resistant, low-friction performance from ceramic balls. Advantages

These features make hybrid bearings an increasingly popular choice for industries requiring both strength and efficiency. Performance and Applications

By aligning material properties with operational requirements, engineers can maximize bearing performance, reliability, and efficiency. ConclusionThe choice of bearing material has a direct impact on performance, durability, and cost.

Ultimately, selecting the right bearing material depends on operational conditions and application-specific requirements. Careful evaluation ensures optimized performance, extended equipment lifespan, and greater cost efficiency in industrial processes. |